低溫封裝玻璃粉1

Low Temperature Sealing Glass 1

Low temperature sealants is a composite material made by blending matrix powder glass with low softening temperature and specially synthesized ceramic filler powder.

By changing the blending ratio and the kind of glass and ceramics, it is possible to change its sealing temperature and thermal expansion coefficient.

When a devitrifiable glass is heated, crystals form in the resulting melt, which then solidifies to produce a highly heat-resistant seal.

Features

- Composite sealing glasses have a short sealing time and excellent ability to seal glas and metal.

- Devitrifiable glasses can be re-fired without deformation.

Properties

| Properties/Glass Code | LS-3075 | BF-0606 | LS-3081 | LS-0118 | LS-0206 | LS-7105 | ||

| Sealing temperature | ℃ | 450 | 485 | 410 | 430 | 450 | 450 | |

| Thermal expansion coefficient | ×10-7/K | 36.5 | 73*1 | 74 | 72.5 | 72 | 85*1 | |

| Density | ×103kg/m3 | 6.91 | 6.05 | 6.89 | 7.05 | 6.82 | 6.37 | |

| Transformation point | ℃ | 300 | 365 | 300 | 317 | 325 | - | |

| Deformation point | ℃ | 330 | 393 | 320 | 337 | 353 | - | |

| Softening point | ℃ | - | 450 | 365 | 390 | 410 | 400 | |

| Volume resisivity Log ρ | 150℃ | Ω•cm | 10.8 | 12.0 | 12.2 | 11.2 | 13.2 | 10.4 |

| Color | Black | Green | Black | Black | Black | Black | ||

| Glass Type | PbO•B2O3 (COM)* 2 |

Bi2O3•B2O3 (COM)*2 |

PbO•B2O3 (COM)*2 | ZnO•PbO•B2O3 (DEV)*3 |

||||

| Application | Alkali-free glass | Window glass , 50 Alloy, 426 Alloy | ||||||

- This thermal expansion coefficient was measured at 30 to 300℃.

- COM:Composite sealing glass

- DEV:Devitrifiable sealing glass

Application Method

1. Printing and Drying

The paste for printing is prepared by adding a vehicle to the sealant and mixing them well. The vehicle is obtained by dissolving acrylic resin in terpineol at a concentration of 5%. The paste obtained is printed on the substrates with 80-100 mesh stainless screen. Drying is carried out at 120℃ for 10-20 minutes.

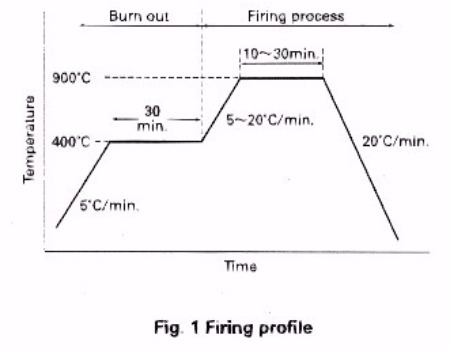

2. Pre-firing

In order to eliminate the resin in the film layers, pre-firing is done in an oxidizing atmosphere such as oxygen or air. Decomposition and firing of resin take place most actively at 320-380℃, so gradual heating is necessary in this temperature range.

| Glass Code | Ti(℃) | T2(℃) |

| LS-3075 | 320 | 380 |

| BF-0606 | 350 | 450 |

| LS-3081 | 320 | 380 |

| LS-0118 | 320 | 380 |

| LS-0206 | 320 | 400 |

| LS-7105 | 320 | 390 |

| Fig. 1 Pre-firing profile | ||

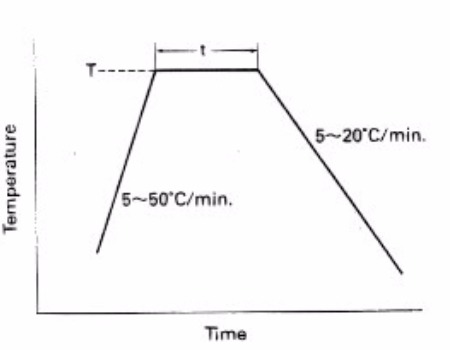

3. Sealing

Sealing is carried out in either an air or a nitrogen atmosphere.

| Glass Code | T(℃) | t(min.) |

| LS-3075 | 450 | 10 |

| BF-0606 | 485 | 10 |

| LS-3081 | 410 | 10 |

| LS-0118 | 430 | 10 |

| LS-0206 | 450 | 15 |

| LS-7105 | 450 | 20 |

| Fig. 2 Sealing profile | ||