低溫共燒陶瓷用原料

Composite Powder for Low Temperature Cofired Ceramics

Composite Powder for low temperature cofired ceramics is a composite material that is made by uniform blending glass and ceramic filler. Firing can be conducted at a low temperature in the range of 870-900℃, which allows the use of highly conductive elements such as gold and silver paste to create a screen print circuit pattern with high electric properties.

Features

- MLS-25M5 is a vitreous material with a low CTE* and a low dielectric constant.

- MLS-25E is a vitreous material with a very low dielectric constant.

- MLS-41 is a devitrifiable material with a high dielectric constant.

- MLS-23K is a a new product with a low dielectric constant and low tan δ.

- MLS-26 is a devitrifiable material with high mechanical strength.

- MLS-63 is a devitrifiable material with high mechanical strength and low tanδ.

| Properties/Glass Code | MLS-25M5 | MLS-25E | MLS-41 | MLS-23K | MLS-26 | MLS-63 | ||||

| Bending strength | MPa | 157 | 125 | 250 | 150 | 320 | 400 | |||

| Dielectric constant | 1MHz,25°C | 4.9 | 3.9 | 17.0 | 3.9 | 7.1 | 8.0 | |||

| 15GHz,25°C | 4.8 | 3.9 | 19.0 | 4.0 | 6.7 | 7.9 | ||||

| Tan δ | 1MHz,25°C | ×10-4 | 25 | 5 | 20 | 5 | 4 | 5 | ||

| 15GHz,25°C | ×10-4 | 47 | 21 | 50 | 15 | 58 | 11 | |||

| Coefficient of thermal expansion | 30-380°C | ×10-7/K | 42 | 60 | 84 | 65 | 58 | 87 | ||

| Density * | ×103kg/m3 | 2.52 | 2.29 | 4.36 | 2.24 | 3.02 | 3.52 | |||

| Transformation point | °C | 500 | 500 | 700 | 525 | 625 | 725 | |||

| Volume resistivity Log ρ | 150°C | Ω•cm | 13.5 | >14 | ─ | >13.8 | 12 | >14 | ||

| Thermal conductivity | W/m•K | 1.9 | 1.7 | 3.1 | 1.7 | 3.9 | 4.1 | |||

| Particle size | D50 | μm | 3.3 | 3.5 | 1.1 | 1.0 | 2.6 | 1.6 | ||

| Dmax | μm | 20 | 20 | 10 | 15 | 15 | 10 | |||

| Glass type | SiO2.B2O3 | Nd2O3.TiO2.SiO2 | SiO2.B2O3 | SiO2.CaO.Al2O3 | ||||||

Application Examples

Method

1. Casting and Printing

Glass-Ceramic powder, binder resin, solvent and plasticizer are thoroughly mixed and cast into a 50-300 μm thick green sheet using the doctor blade method. Individual sheets are cut into appropriate sizes from the green sheet and punched with via holes and then screen-printed with a circuit pattern.

2. Lamination

Green sheets are laminated at 50-100℃ and under 10-35 MPa pressure.

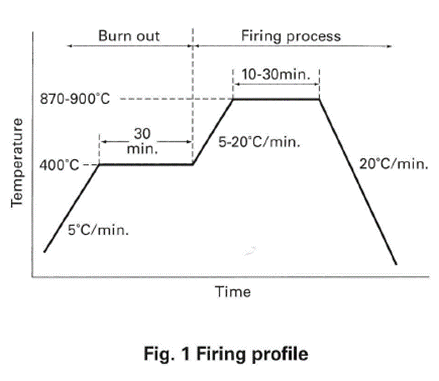

3. Firing

Firing is carried out in the air.